hatchery biosecurity

RSSBP provides tools to SUPPORT, IMPROVE, and DOCUMENT facility disease risk management

Assess your facility disease risk

Consider the PATHWAYS for disease transfer and evaluate facility biosecurity protocols in place.

Identify any gaps in protocols or employee training that would increase biosecurity and reduce risk of disease transfer.

ANIMALS – What protocols are in place for broodstock sourcing, holding, spawning, and disposal to ensure disease doesn’t transfer to other areas of the hatchery or to the source water? Do you keep detailed broodstock and spawn records which enable traceback if a disease issue should occur?

WATER – What are the water treatment protocols? Do you keep records of What is the potential for transfer of untreated water to the treated water areas? How are these areas separated? Are protocols in place to avoid splashing and tracking untreated water into other areas?

FOMITES (non-human)– What protocols are in place for equipment such as buckets, sieves, etc. that is moving through the hatchery? Are there disinfection protocols for shared equipment? Do you have clearly labeled equipment specific to different areas of the hatchery? (algae, larvae, spawning, broodstock)

FOMITES (human) – What protocols are in place to avoid disease transfer from workers who have duties in the field and the hatchery? Do you train workers in biosecurity? Do you have procedures in place for workers entering the hatchery from the field such as hand washing and changing clothes?

Align practices w/ RSSBP BMPs to reduce risk of disease transfer

Review the RSSBP Best Management Practices (BMPs) and ensure you are meeting these practices.

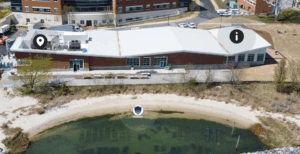

Check out this virtual hatchery tour to see an example of the BMPs in a facility.

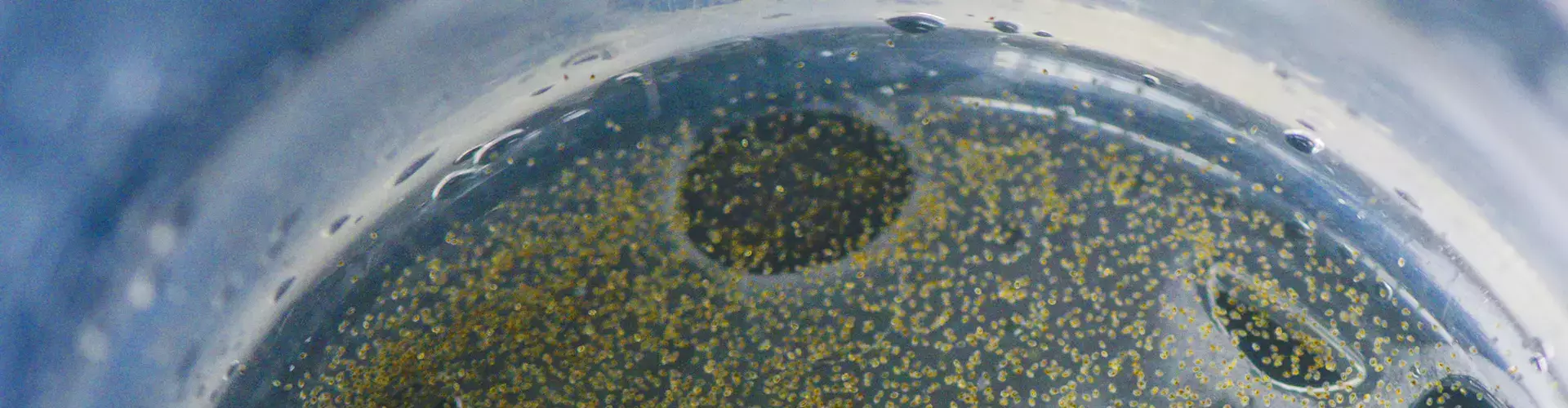

Monitor larval health and obtain routine product health exams

Facilities should develop a relationship with a shellfish pathologist to obtain routine product health exams (which demonstrate the effectiveness of the biosecurity measures) and health exams on animals exhibiting signs of illness or experiencing unexplained mortality. Larval mortality is complex and can be attributed to a number of factors that may or may not involve disease. Sending samples doesn’t count against operators, rather it demonstrates appropriate biosecurity measures are in place. Ruling out POCs/disease is critical to mitigate product loss and disease spread.